About Us

Teconnex

A world leader

with a global presence

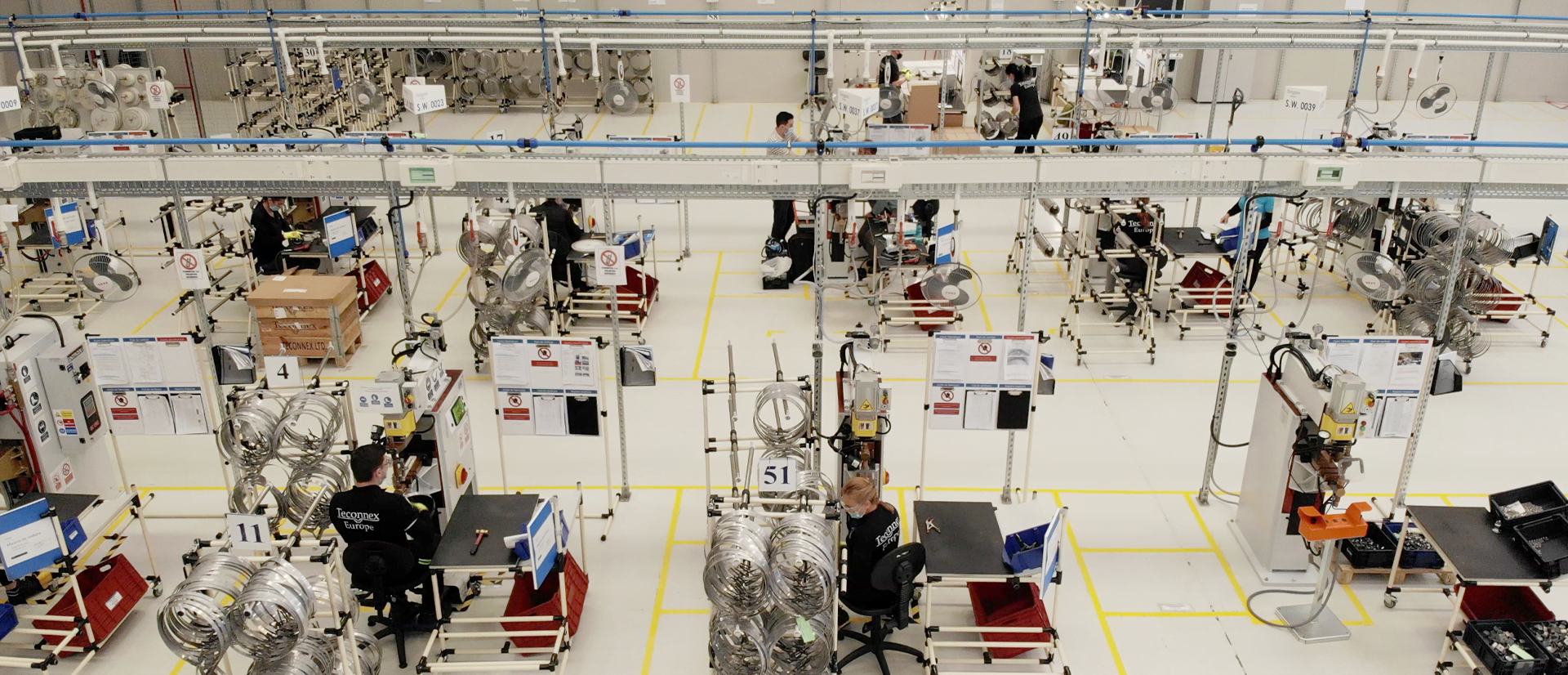

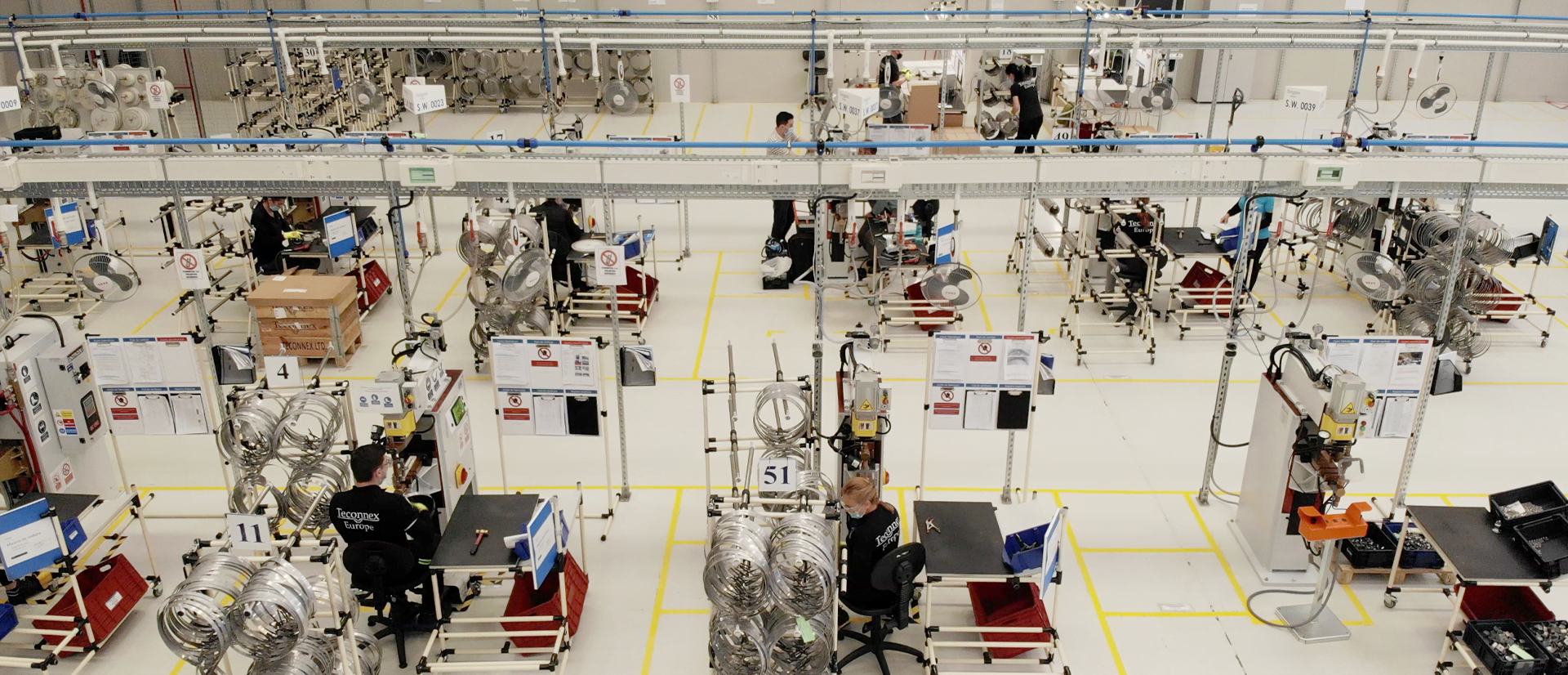

Teconnex is a global leader in providing engineered clamping solutions for the emissions market while investing in new technology through our Product Diversification Programme.

With facilities in four continents, our continuous improvement has seen us diversify our production to meet the requirements of a number of industry sectors.

Our history began with manufacturing technical joint solutions and continues to grow on a global stage but Teconnex today has expanded into the world of Bellows, power, aerospace, automation, tooling and more in the future.

Our History

Click on the bar below for more information about each year.

Smith & Johnson

1956Smith & Johnson opened its doors

Connectors Ltd

1968Connectors Ltd was formed

Hexadex Ltd

1987UK manufacturing group Hexadex Ltd purchases Connectors Ltd

Merger of Connectors Ltd and Smith & Johnson

1998Teconnex Limited is created following the merger of Connectors Ltd and Smith & Johnson, under the Hexadex umbrella.

Joint venture in Kunshan

2012Teconnex and Funwick set up a joint venture in Kunshan, China

Mexico Facility

2016Teconnex continues expansion with South America facility opening in Monterrey, Mexico

Bellows Technology

2017Teconnex acquires Bellows Technology in New Mills, near Stockport

Expanding further

2018Teconnex global expansion continues with sites in Cluj, Romania and Pune, India

Diversification programme

2019Pushing forward with our diversification programme in the battery, aerospace, automation & tooling side of the business